CREATING VALUE IN YOUR CABLE & WIRE MANUFACTURING BUSINESS

Applying today's best practices, leveraging our exceptional expertise in manufacturing and distribution, and utilizing a flexible and proven methodology, our services are geared to deliver results you never imagined possible. We collaborate with the following industry-leading platforms:

Revolutionizing Material Requirement Planning (MRP)

In the fast-paced world of manufacturing, Material Requirement Planning (MRP) has been a cornerstone for ensuring that customer demand is met with timely supply. However, as industries grow more complex, traditional MRP systems are struggling to keep pace with the dynamic demands of modern manufacturing. This is especially true in the Wire and Cable (W&C) industry, where raw material costs and supply chain disruptions pose significant challenges.

In this blog, we’ll explore how Hype Software Studio is revolutionizing MRP with its Innovative Cable S/4 Solutions, enabling manufacturers to transition from traditional MRP to more agile, demand-driven models. We’ll also dive into a real-world use case to illustrate the transformative impact of these solutions, including analytical data, KPIs, and financial outcomes that demonstrate improved ROI.

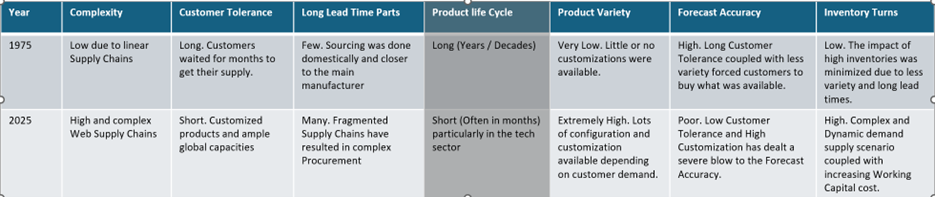

The Evolution of MRP: From the 1970s to Today

MRP was first introduced in the 1970s as a way to manage inventory and resources more effectively. However, over the past five decades, the manufacturing landscape has undergone radical changes. Traditional MRP systems, which rely on stable lead times and repetitive historical demand patterns, are no longer sufficient in today’s volatile market.

Challenges of Traditional MRP:

- Forecast Inaccuracy: Forecast accuracy has plateaued, with even the best-in-class accuracy in the W&C industry not exceeding 70%. This leads to frequent stock-outs or overstocking, both of which impact profitability.

- Slow Response to Change: Traditional MRP struggles to adapt to sudden changes in demand or production schedules, leaving businesses vulnerable to supply chain disruptions.

- Static Inventory Levels: Traditional MRP systems often rely on static inventory levels, which must be manually updated, leading to inefficiencies and increased working capital costs.

- Overwhelming

Data Volume: MRP systems generate vast amounts of data,

which can be overwhelming for decision-makers if not properly analysed.

MRP was

first introduced in the 1970s as a way to manage inventory and resources more

effectively. However, over the past five decades, the manufacturing landscape

has undergone radical changes. Traditional MRP systems, which rely on stable

lead times and repetitive historical demand patterns, are no longer sufficient

in today’s volatile market.

The Cable & Wire Industry: Unique Challenges

The Cable & Wire industry faces unique challenges that exacerbate the limitations of traditional MRP systems:

- Raw Material Costs: Up to 70%-80% of cable costs are attributed to raw materials, particularly non-ferrous metals like copper and aluminum, as well as petroleum derivatives used in insulation and sheathing materials (e.g., PVC, XLPE). These materials are subject to price volatility and supply chain disruptions.

- Supply Chain Uncertainties: Imported raw materials are further impacted by shipping delays, government regulations, and duties, making it difficult to maintain consistent inventory levels.

Shelf-Life

Constraints: Many materials used in cable manufacturing,

such as plastics and polymers, have limited shelf lives. Planners must

constantly monitor and manage inventory to ensure materials are used

before their performance deteriorates.

Hype's Innovative Cable S/4 Solution: A game changer for Cable & Wire Industry

Hype Software Studio offers two Material Planning Models to help cable manufacturers navigate these challenges:

- Traditional Material Requirement Planning (MRP-I)

- Modern Demand-Driven Material Requirement Planning (DDMRP)

Manufacturers can choose either model or customize a combination of both to create a more agile and resilient supply chain

Traditional MRP in Cable S/4 Solution

Hype’s Cable S/4 Solution enhances traditional MRP with advanced features designed to address the specific needs of the W&C industry:

1. Inventory Analysis and Segmentation

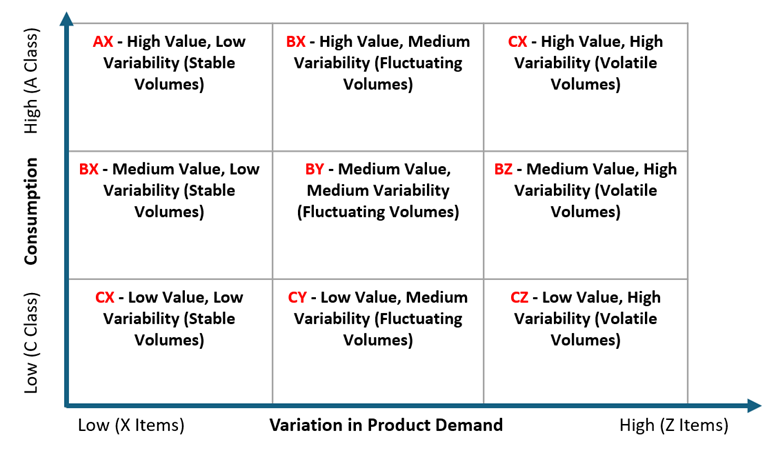

- ABC, XYZ, and FSN Analysis: These inbuilt inventory segmentation tools help businesses categorize products based on consumption patterns, demand variability, and shelf-life constraints.

- Safety Stock Strategies: By combining ABC and XYZ analysis into a 3x3 matrix, businesses can develop tailored safety stock strategies for different material groups.

2. Advanced Safety Stock Calculations

- Hype’s solution offers six built-in models for safety stock calculations, including:

- Normal Distribution Method with uncertainty of demand and lead times.

- Maximum minus Average Method.

- Subjective Judgement for unique scenarios.

- These models help businesses maintain optimal inventory levels, reducing the risk of overstocking or stockouts.

3. Dynamic Reorder and Maximum Stock Levels

- Reorder and maximum stock levels are calculated using historical consumption data, lead times, and demand forecasts.

- The system ensures that inventory levels are aligned with actual demand, preventing overstocking and minimizing working capital costs.

4. Net Stock Position (NSP) Reporting

- NSP reports provide real-time visibility into stock levels, on-order quantities, and demand forecasts over a cumulative period of 3 to 12 months.

- Planners can quickly assess the impact of new orders and ensure timely delivery, subject to capacity availability.

Drawbacks of Traditional MRP in Cable & Wire Manufacturing

While Hype’s Cable S/4 Solution enhances traditional MRP, it’s important to acknowledge its limitations:

- Static Inventory Levels: Traditional MRP relies on static safety stock levels, which must be manually updated, leading to inefficiencies.

- Historical Data Dependency: MRP systems base inventory levels on historical data, which may not accurately predict future demand, especially in made-to-order scenarios.

- Limited Adaptability: Traditional MRP struggles to adapt to sudden changes in demand or production schedules, potentially leading to stockouts or excess inventory.

Demand Driven MRP(DDMRP): The Future of Material Planning

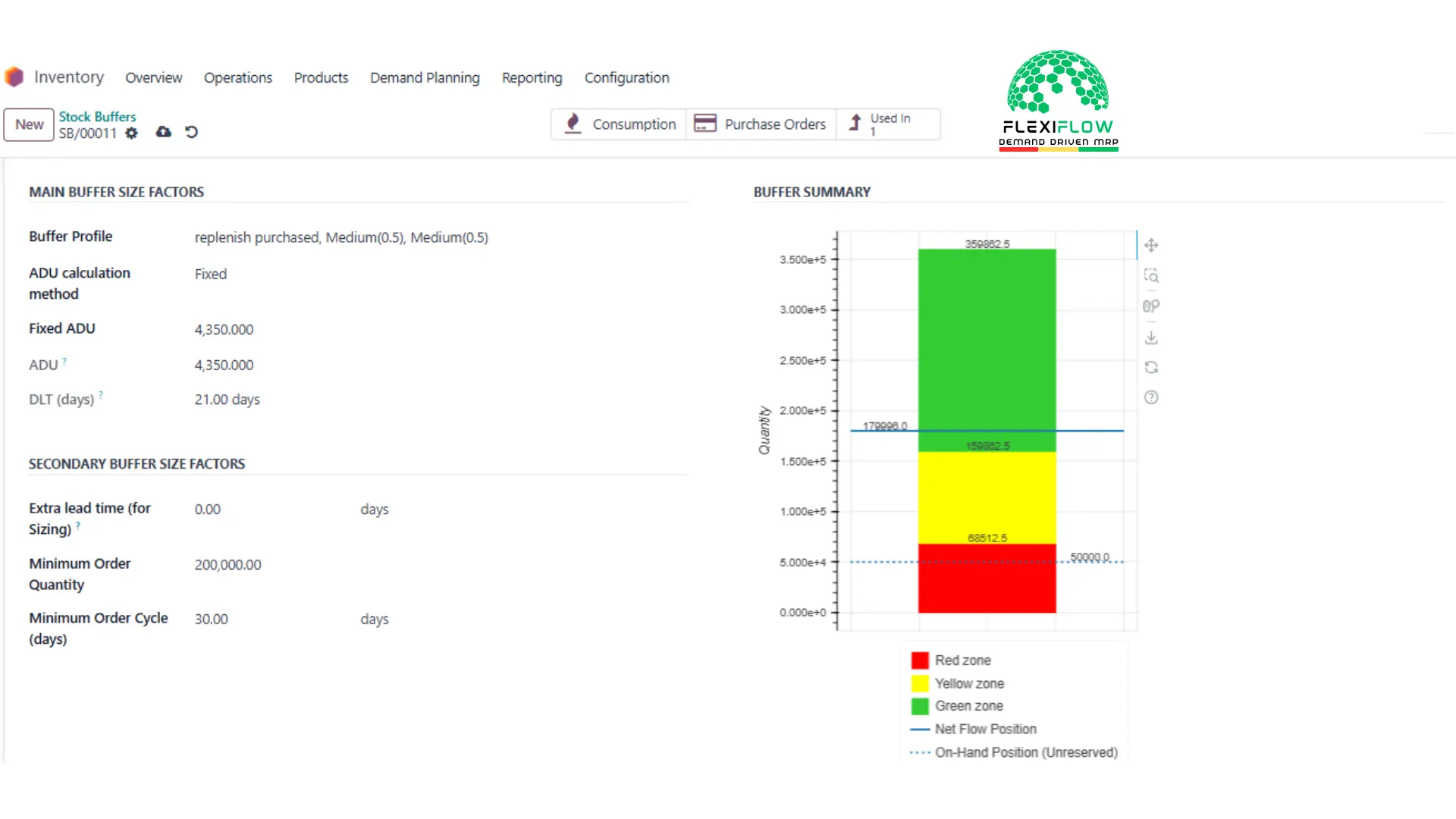

FlexiFlow: Demand Driven Material Planning

To address the limitations of traditional MRP, Hype offers Demand-Driven MRP (DDMRP), a modern approach that aligns inventory levels with actual demand rather than forecasts. DDMRP focuses on:

- Buffer Management: Inventory buffers are dynamically adjusted based on real-time demand signals, ensuring optimal stock levels.

- Flow-Based Planning: Materials are replenished based on actual consumption, reducing the risk of overstocking or stockouts.

- Agility and Resilience: DDMRP enables businesses to quickly adapt to changes in demand or supply chain disruptions, improving overall agility and resilience.

The

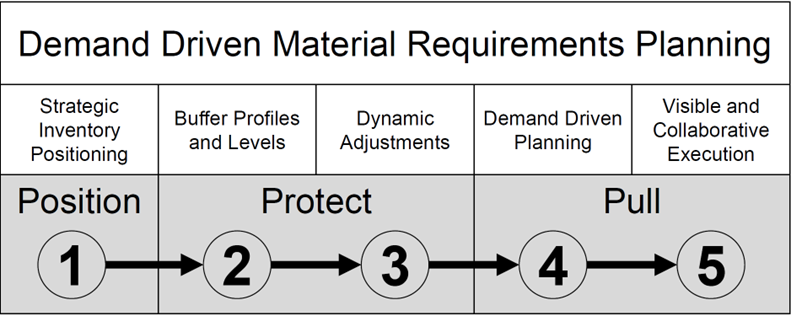

Five Components of DDMRP:

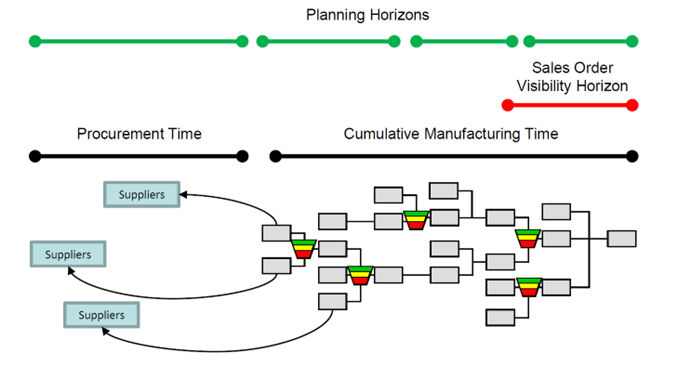

Strategic Inventory Positioning:

- This is achieved by “Decoupling” – Creating

independence between supply and use

of material.

The Decoupling point is the location in the product structure where the inventory needs to be placed to create the independence, and the amount of Inventory is called the Decoupling Inventory. - These points are located as close as possible to the Sales Order Visibility Horizon.

- Independent Planning Horizons occur between the decoupling points

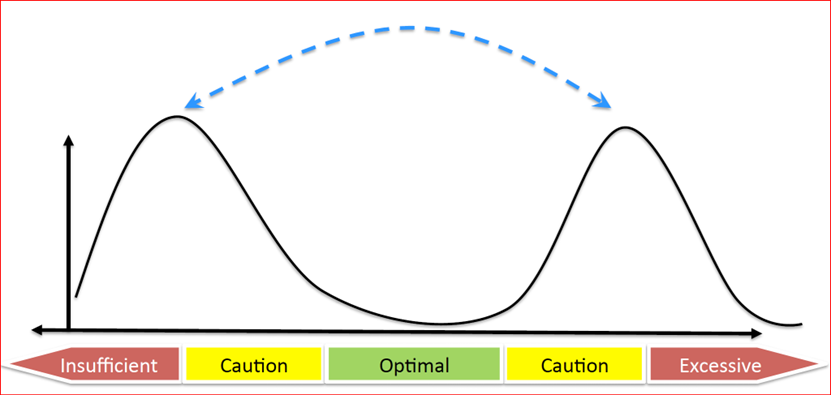

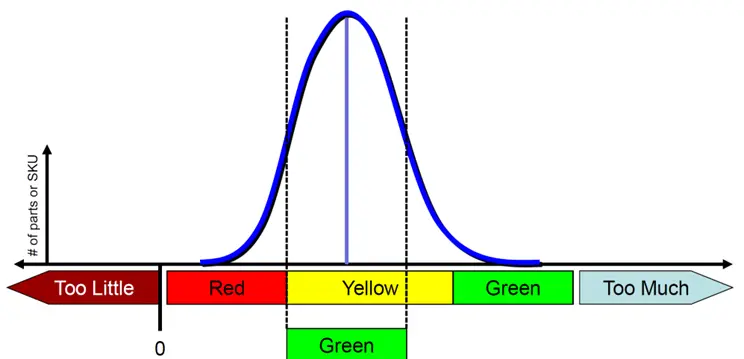

Buffer Profiles and Levels:

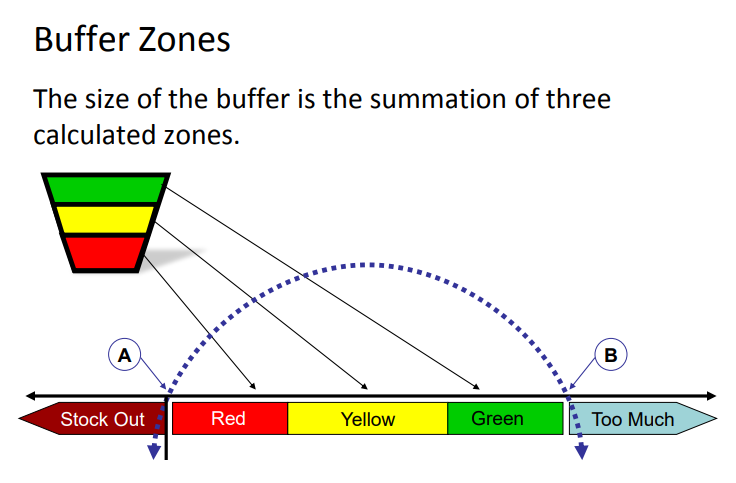

- Optimal Inventory can be an Asset, but too little or too much can be a Liability.

- This range of optimal inventory is known as the Buffer and the size of this buffer is calculated as the sum of three distinct zones – Red, Yellow and Green

- Each zone has a purpose and there is a specific way to calculate them.

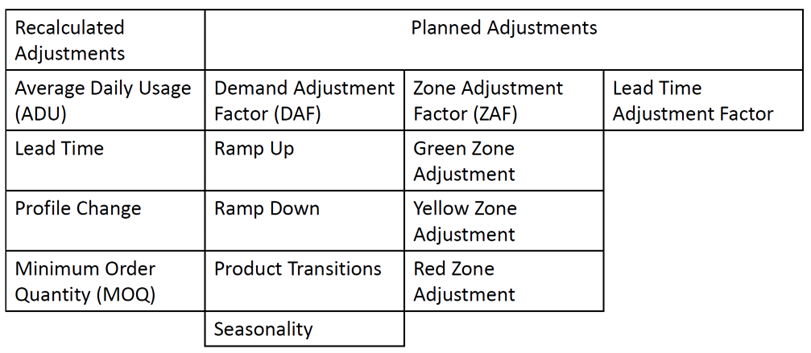

Planned Dynamic Adjustments:

- Planned adjustments are based on certain strategic, historical, and business intelligence factors.

- These planned adjustments are manipulations to the buffer equation that affect inventory positions by raising or lowering buffer levels and their corresponding zones at certain points in time. There are three primary types of planned adjustments:

- –Demand Adjustment Factor

- –Zone Adjustment Factor

- –Lead Time Adjustment Factor

Demand Driven Planning:

- Net Flow Position (NFP) is the key in the DDMRP process for Supply Order Generation.

- It takes into consideration the spikes in the demand over the Supply Planning Time Horizon and alerts if a new Supply Order has to be generated.

- The NFP is calculated everyday for all items that come under the purview of DDMRP, but they may not be ordered everyday.

- Following the NFP Calculation, the system would calculate the Average On Hand position and its range.

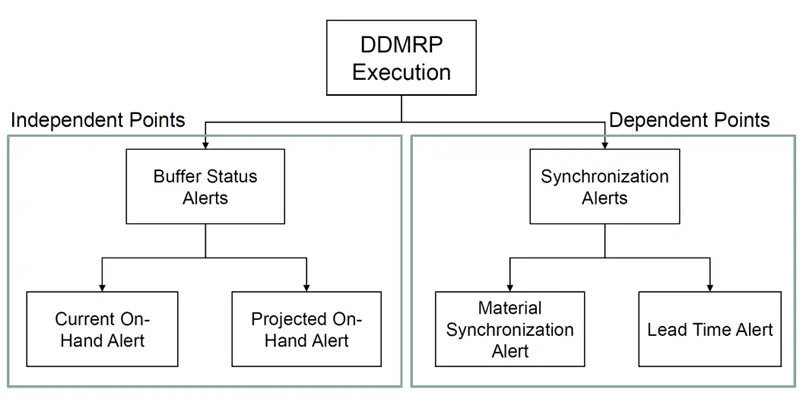

Visible and Collaborative Execution:

- DDMRP Execution Alerts are based on Buffer Status Alerts and Synchronization Alerts.

- Between the On Hand Status and future Net Flow Position is the fluid Execution Window that can either protect your availability or delve deeper into Stock out situation.

- DDMRP Execution dashboards enable Planners to visualize the impact of both scenarios, thus enabling them to take the right decision.

Why to choose

Cable S/4 Solution.

Hype’s Innovative Cable S/4 Solutions offer several key benefits for cable manufacturers:

- Improved Forecast Accuracy: Advanced inventory analysis and safety stock calculations help businesses maintain optimal stock levels, reducing the risk of stockouts or overstocking.

- Real-Time Visibility: NSP reports provide real-time insights into inventory levels, enabling faster decision-making.

- Customizable Planning Models: Businesses can choose between traditional MRP, DDMRP, or a combination of both, depending on their unique needs.

- Cost Savings: By optimizing inventory levels and reducing working capital

costs, Hype’s solutions help businesses improve profitability.

Recognized by the Demand Driven Institute, Integrated Business Solution Cable S/4 streamlines planning, execution, and inventory management across the entire supply chain. Businesses achieve shorter lead times, lower inventory costs, improved service levels, and maximum ROI on working capital.

Stay ahead with FlexiFlow—your key to a more efficient, adaptive, and demand-driven supply chain.

Ready to explore DDMRP?

Book your time slot now

Each time slot includes a 1h discovery period.

Driving progress

with Cable S/4 in

Cable Industries

Empowering cable manufacturing with next gen- Integrated Business Operations Management Solution.