FlexiFlow-

Flexibility & Adaptability in Materials Planning

A modern approach to material control and replenishment that enhances traditional MRP by dynamically adapting to real-time demand fluctuations.

Smart demand planning with intelligent logic, statistical precision, and seamless collaboration.

Strategically position pull-controlled inventory to safeguard production schedule and prevent shortages.

Accelerate Smarter Planning with FlexiFlow DDMRP

Mitigate Supply Chain Uncertainty with Smarter Inventory Management

Optimize your inventory investment to absorb risk more effectively at a lower cost. Through advanced, coordinated planning, you can navigate business uncertainties, rising customer expectations, and demand-supply fluctuations.

Address the complexities of modern supply chains with a proactive approach, ensuring resilience and readiness for disruptions in an unpredictable world.

Optimize Inventory Investments

Achieve superior customer service without overinvesting in inventory. With intelligent optimization, you can strike the perfect balance between stock levels and working capital, leveraging advanced scenario planning and segmentation strategies to meet demand efficiently.

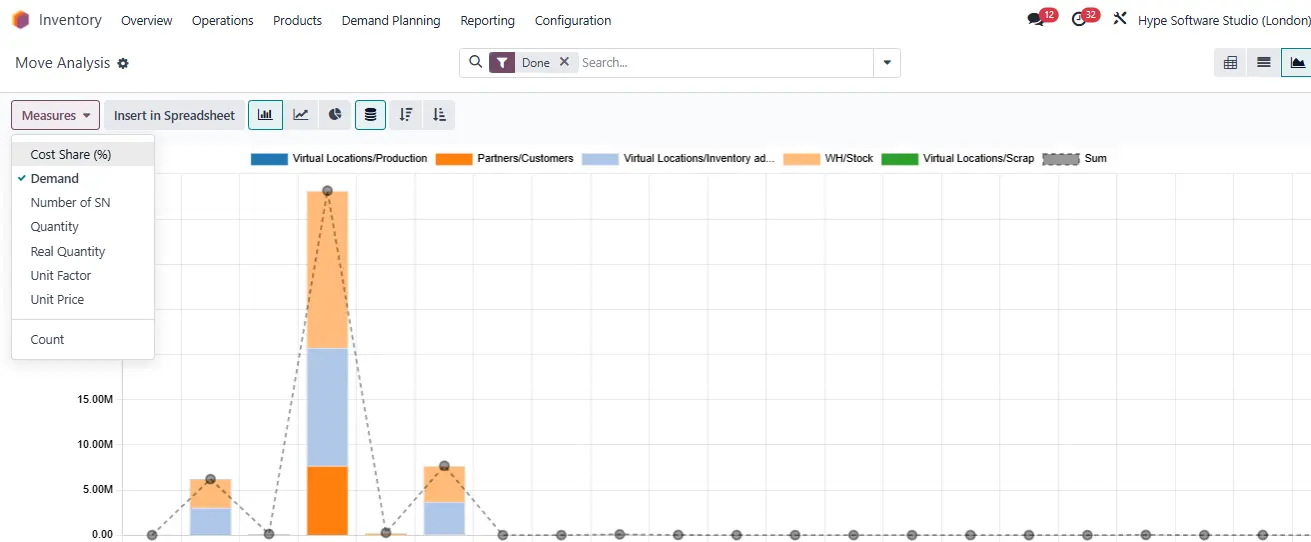

Real-Time Visibility & Control

Gain instant insights with real-time reports on stock levels, inventory movements, and production status, empowering you to

make data-driven decisions with confidence.

Smart Inventory Optimization across Multiple

Stages

Synchronize planning across multiple locations in your organization to prevent overstocking while ensuring service goals are met. Multistage optimization calculates precise inventory targets by considering network interdependencies, optimizing stock levels for finished goods, components, raw materials, and semifinished products.

Insights for

Smarter Decisions

Leverage built-in analytics to visualize your product network and inventory distribution. Identify key factors influencing stock levels and take targeted actions to optimize inventory and reduce excess.

✽ What FlexiFlow-DDMRP Software Offer

Discover our

FlexiFlow benefits

Smart Inventory

Optimization

FlexiFlow’s intelligent engine empowers planners and buyers by automating supply network optimization, reducing firefighting, and eliminating inefficiencies caused by shortages and excess inventory

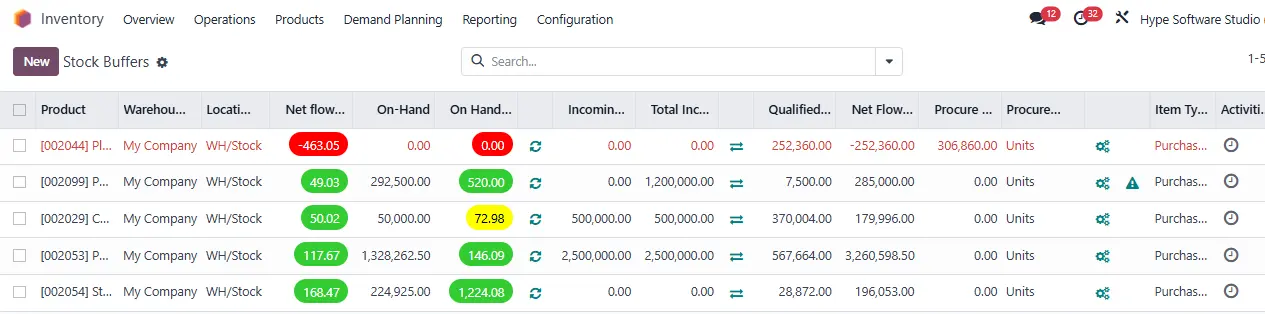

Daily Monitoring and Smart Alerts

FlexiFlow continuously analyzes supply and demand, delivering real-time planning and execution alerts. This proactive approach eliminates manual guesswork and streamlines decision-making.

Dynamic Supply Chain Alignment

Unlike traditional MRP, FlexiFlow bases supply order generation on actual consumption rather than unreliable forecasts. This creates a stable, demand-driven supply chain with consistent supplier signals, minimizing last-minute adjustments.

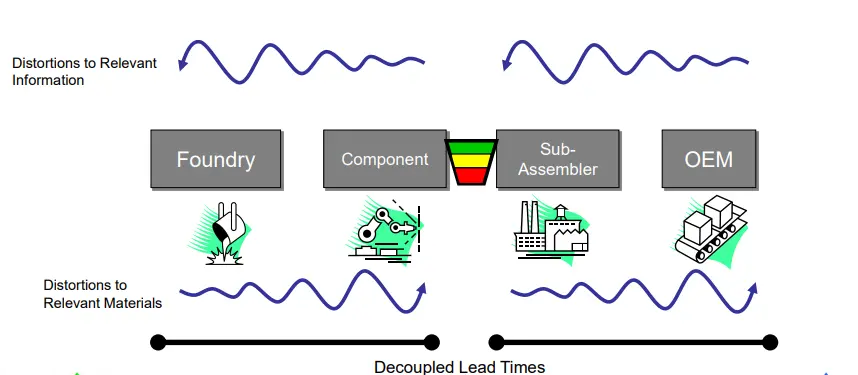

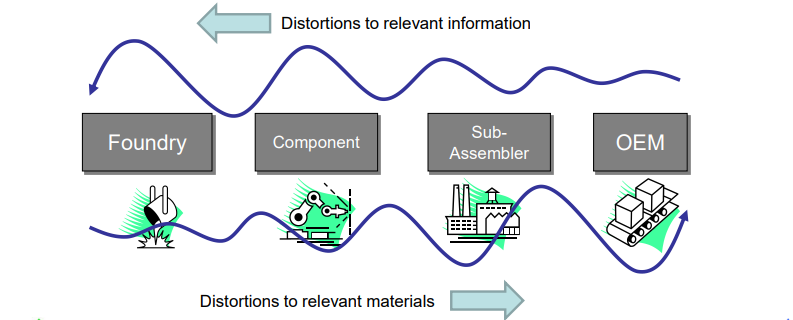

Reducing Variability & Demand Distortions

By dynamically adjusting inventory levels and order generation, FlexiFlow minimizes supply chain fluctuations, ensuring steady stock availability and mitigating disruptions while stabilizing supplier signals .

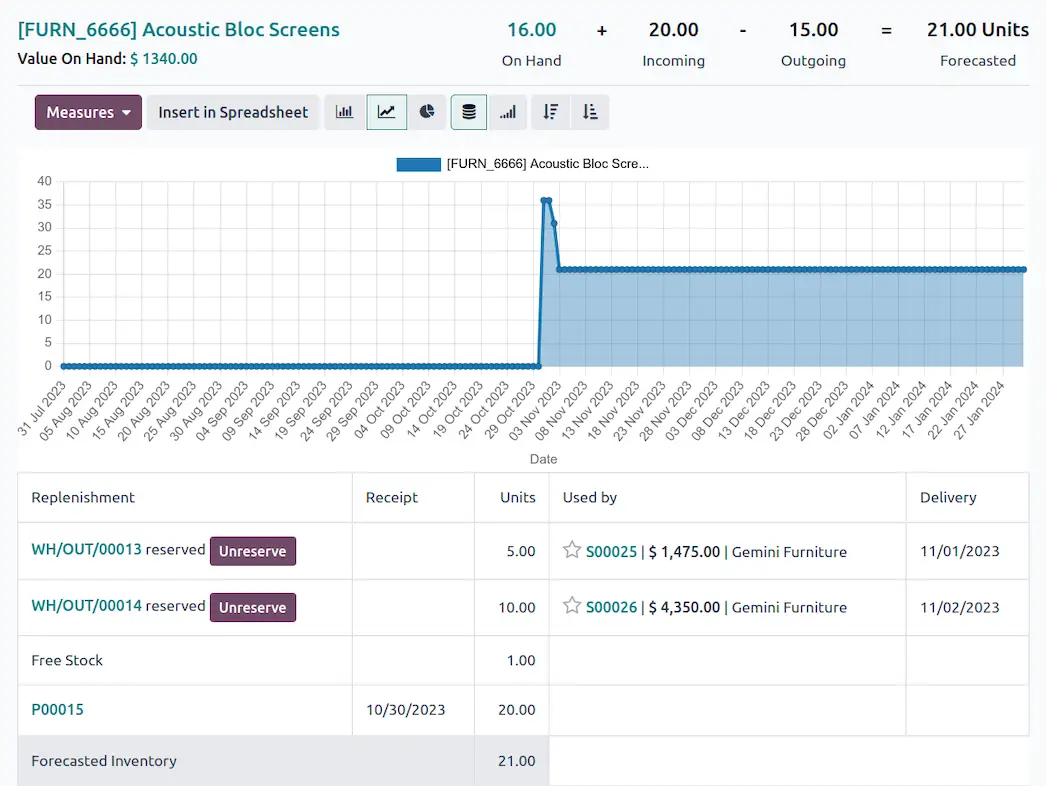

Real-Time Supply Chain Visibility

FlexiFlow monitors inventory levels and prioritizes supply orders based on stock availability rather than just due dates. This approach prevents stockouts, enhances responsiveness, and optimizes supply chain performance.

Effortless Execution & Strategic Control

With automated order recommendations and seamless integration, planners and buyers can focus on strategic decisions instead of manual workarounds. FlexiFlow ensures supply orders align perfectly with real market needs.

FlexiFlow DDMRP – Transforming Supply Chain Performance

FlexiFlow enables seamless planning and execution for your demand-driven supply chain, delivering substantial operational benefits.

Cut excess stock by up to 65%, freeing up working capital while maintaining optimal availability.

Achieve up to 100% on-time delivery, ensuring seamless order fulfillment and customer satisfaction.

Improve inventory turnover by up to 400%, reducing waste and maximizing asset utilization.

Enhance responsiveness with up to 80% shorter lead times, adapting quickly to market demands.

Minimize outdated inventory by up to 90%, optimizing stock levels and cutting unnecessary costs.

Optimize the supply chain planner's availability, improving efficiency by up to 25%.

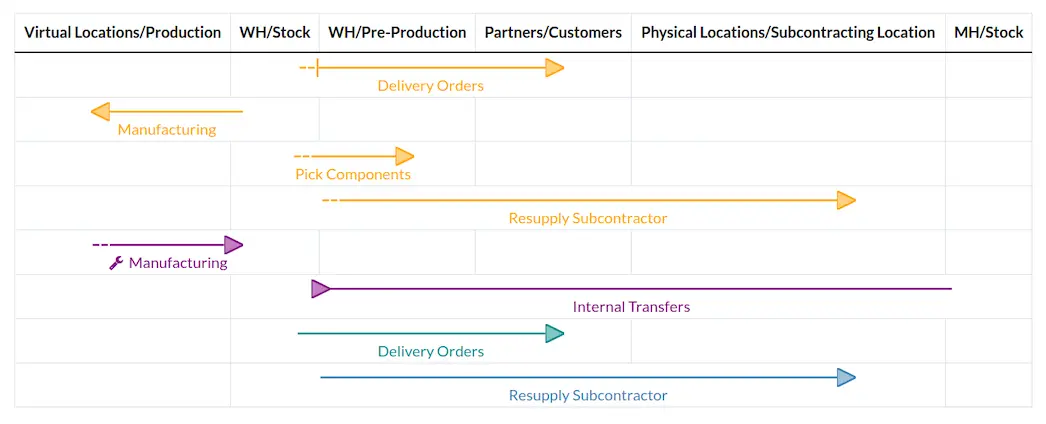

How Does FlexiFlow Demand-Driven MRP Works.

Traditional MRP follows a push-based approach, driving inventory based on forecasts. In contrast, FlexiFlow DDMRP operates on a pull-based system, dynamically adjusting inventory levels based on actual demand. This method reduces reliance on forecast accuracy, minimizes variability, and prevents excess stock and shortages.

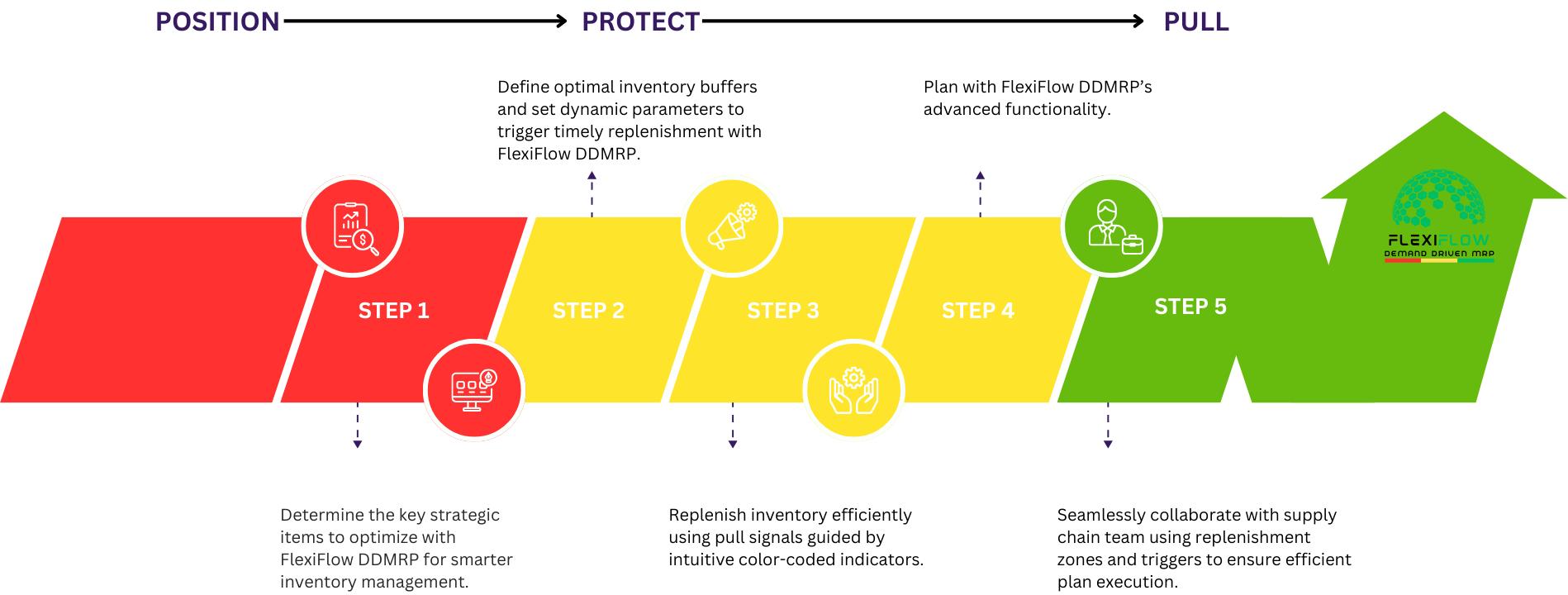

At its core, DDMRP follows the principles of “Position, Protect, and Pull”:

- Position – Identify strategic materials at critical supply chain points to ensure availability.

- Protect – Use buffer inventory dynamically to safeguard key items without overstocking.

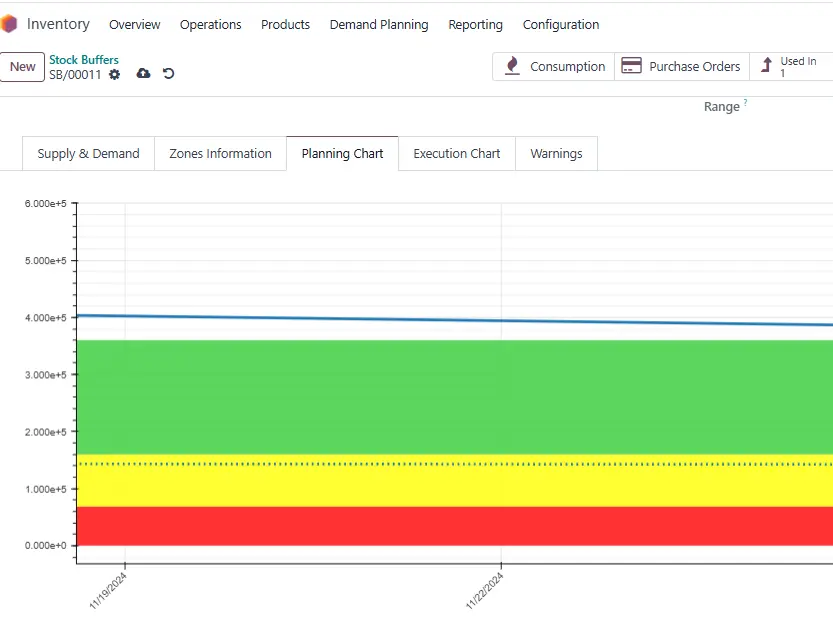

- Pull – Replenish inventory based on real-time demand signals, using intuitive visual indicators.

The FlexiFlow DDMRP Process:

- Identify the decoupling point within the business to optimize the overall materials and information flow.

- Set buffer levels and replenishment triggers.

- Replenish using pull signals and color-coded alerts.

- Plan effectively with FlexiFlow’s intelligent tools.

- Collaborate with supply chain team using replenishment triggers to execute the plan.

With FlexiFlow DDMRP, businesses achieve a resilient, demand-driven supply chain—optimizing inventory, reducing lead times, and improving overall efficiency.

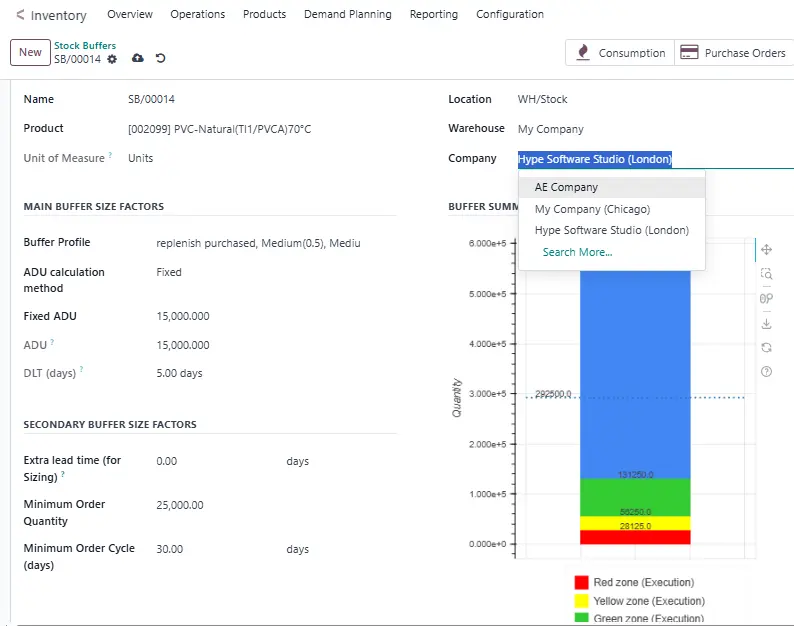

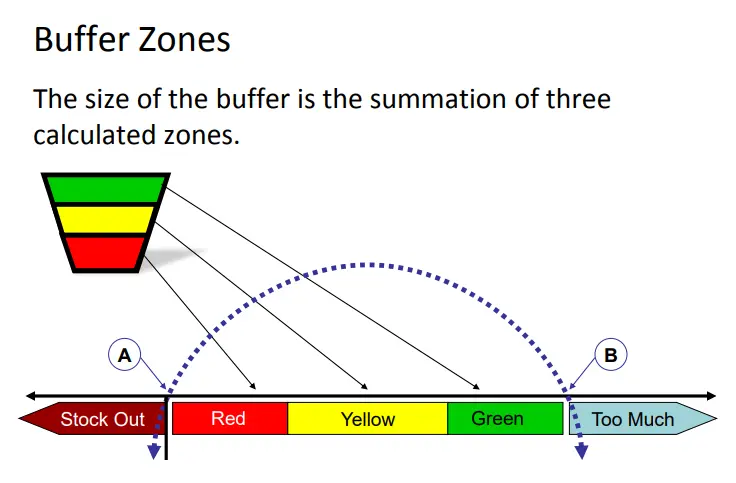

Each Zone's Purpose and Calculation in Buffer Management

Each buffer zone serves a distinct role in optimizing inventory replenishment and ensuring supply chain stability:

- Order Generation Zone: Determines how frequently orders are placed and sets the minimum order quantity to maintain efficiency.

- Demand Coverage Zone: Ensures the buffer can adequately meet demand fluctuations, preventing stockouts.

- Safety Zone: Acts as a protective layer within the buffer, mitigating risks associated with supply variability and unexpected demand spikes

Frequently asked questions

Here are some common questions about our company.

Demand is the requirement for a product or component. For finished goods, demand typically comes from customer orders, warehouse transfers, or internal use. For raw materials and components, demand is mainly driven by production needs, replacements, or sales to other business units.

FlexiFlow is a fully compliant Demand-Driven Material Requirements Planning (DDMRP) software designed to optimize material flow, reduce lead times, and improve supply chain efficiency. It integrates advanced planning methodologies with user-friendly functionality to support manufacturers and supply chain professionals.

Material replenishment is the process of restocking materials or parts as they are consumed. Businesses maintain an inventory of essential components and order replacements when stock reaches a predefined threshold, ensuring uninterrupted operations. Various replenishment strategies exist, including Kanban, MRP-based scheduling, and DDMRP-driven replenishment.

Kanban is a visual replenishment system that uses signals (e.g., cards, bins, or digital alerts) to trigger material restocking. While Kanban is effective for high-volume, repetitive production, DDMRP provides a more flexible, demand-driven approach suited for volatile supply chains. Unlike Kanban, which primarily focuses on execution, DDMRP integrates planning, execution, and real-time adaptation to demand fluctuations.

MTO is a custom manufacturing approach where production starts only after receiving a customer order. This model minimizes inventory but extends lead times. DDMRP helps MTO businesses by improving material flow, ensuring faster response times, and reducing variability in supply chains.

DDMRP is a multi-echelon planning and execution methodology that combines elements of traditional MRP, Lean, Six Sigma, and the Theory of Constraints. It operates through six key components:

- Strategic Decoupling – Placing stock buffers at critical points to protect against supply chain disruptions.

- Buffer Profiles & Levels – Defining dynamic inventory buffers based on demand patterns and variability.

- Dynamic Buffer Adjustments – Adapting buffer levels to real-time changes in lead time, demand, and supply.

- Demand-Driven Planning – Using the Net Flow Equation to optimize material replenishment daily.

- Visible & Collaborative Execution – Managing open orders using Buffer Status Alerts and Synchronization Alerts to prevent disruptions.

- Tactical Adaptation – Continuously improving the supply chain model based on past and projected performance using Demand Driven S&OP (DDS&OP).

DDMRP enhances MRP by replacing push-based planning with a demand-driven pull system for strategic parts. Unlike Kanban, which works well for repetitive manufacturing, DDMRP is more adaptive to variability and demand fluctuations.

Faster lead times, optimized inventory, higher service levels, and a more responsive supply chain that reduces waste and enhances flow.

Industries with complex supply chains, long lead times, and high demand variability, including manufacturing, aerospace, automotive, pharmaceuticals, and consumer goods.

By reducing material shortages, improving lead time predictability, and enabling faster responses to custom orders.

A VUCA world is a world that is volatile, uncertain, complex, and ambiguous. It's a framework that helps people understand and respond to the challenges of this complex and unpredictable world.

To survive in a VUCA world, you can:

- Be adaptable, open, and resilient

- Develop a mindset that embraces change

- Be aware of what's going on around you

- Pay attention to the news, current events, and global trends

- Be proactive, not reactive

- Develop strong learning agility